Together with Ramirent and SRV, Kaltiot carried out construction phase indoor positioning in REDI, one of the largest construction projects in Finland at that time. The Kaltiot Smart Tracker system was used to monitor the location of scissor lifts on the project site.

The REDI shopping center has a total area of approximately 60 000 m2, including five floors of retail premises and two floors of parking halls. In addition to the shopping center, REDI also has eight residential towers. The first one, Majakka, was the highest residential building in Finland at the time of completion.

The problem

On large, complicated sites with hundreds or thousands of workers and shared equipment, others are always moving the tools you need and you don’t know where to look for them. Workers can spend a few hours a week, or even half a work day, looking for the tools they need to finish their assigned tasks. When you multiply even an hour or two a week across hundreds of workers and months of project time, the savings from asset tracking become dramatic.

The challenge

The construction site environment brings many challenges to the tracking solution, including constant progress in construction with evolving spaces, numerous subcontractors, and limited network connections in underground floors and concrete structures. Workplaces are often divided into indoor and outdoor spaces, and the tracking solution has to work seamlessly throughout the entire area. On top of these challenges, the tracker needs to be battery-operated and run for as long as possible to make operation smooth.

The solution

Ramirent and SRV are constantly looking for new innovations on the construction site. They took on Kaltiot Smart Tracker to help locate the equipment and improve productivity on the construction site.

Smart Tracker provided information about the location of equipment anywhere on the site, for all workers, which can significantly reduce the time workers spent searching for what they needed.

225 tracking beacons were installed at the site. The tracking made use of small beacons and the Kaltiot Smart Tracker smartphone application. The beacons were attached to the equipment to be tracked. The beacons sent out a wireless signal to nearby smartphones which had the app installed. The beacons’ locations were calculated based on smartphone locations and signal strength from beacon to phone.

Indoors, fixed reference point beacons were installed at a suitable distance apart around the shopping mall. The location of each fixed beacon was marked with specific coordinates. Fixed beacons were used to help locate the movable beacons indoors.

The Smart Tracker application ran in the background and did a constant scan for nearbry beacons. The application only needed to be turned on when the phone user arrived at the work site for the day. This step could also be automated if needed.

The app

The application had three views to meet different user needs: Devices, Nearby, and Map.

- Devices view showed all the devices that have been added to the system. The user could search for a specific piece of equipment using the search field to see the equipment on the map.

- Nearby view showed all tracked equipment near the phone, as well as the distance away.

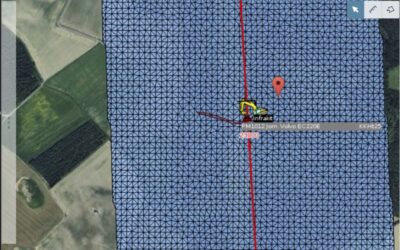

- Map view showed all tracked equipment on a map.

Better communication improves efficiency

To improve the overall on-site efficiency, cooperation and knowledge sharing between the parties is a prerequisite. By providing the location of equipment, tools, personnel and incoming material to all parties working on site with a mobile application and web view, the parties can contribute to both their own and other’s work efficiency.

Miscommunication and lack of technical tools causes inefficiency

To track a variety of movable equipment, transport vehicles or trolleys, containers, tools, or staff from a single system, Smart Tracker is the solution. Smart Tracker provides real-time or last seen location, route, and occupancy of the item. The data provided by Smart Tracker can be tailored to various parties and data can be processed in the desired way, for example, in their own operational development.